Nitrogen is not Nitrogen

Dry nitrogen purging when welding pipeworkWhy do we nitrogen purge? - Nitrogen purging is an integral process in producing a quality HVAC-R system, however there are some factors to be aware of. Brazing at such high temperatures results in a heavy black oxide (cupric oxide), forming both inside and outside of the pipe. On cooling, this oxide flakes off to form scale. While only a cosmetic issue on the outside, inside the tube the oxide flakes are carried by the refrigerant through the system. This can result in loss of performance or failure of a system component.

This problem has long been an issue when brazing HVAC-R pipework. It has become more important with the change from HCFC refrigerants, like R-22 that use mineral oil, to HFC refrigerants (R410a) using polyol ester (POE) oils. POE oils have a solvent effect and can ‘scrub’ the copper tube walls. Oxide from tube walls and loose scale can circulate through the system, usually ending up in the crankcase of the compressor. The following picture identifies when dry nitrogen has been used during the brazing process (left pipes) and when it is not used (right pipes).

As reported in our last newsletter, the use of dry nitrogen during installation must follow the Australian and New Zealand refrigerant handling code of practice 2007, part 2, including clauses:

- 5.25 After pipework has been fixed in position, dry nitrogen must be passed through the system to remove oxygen prior to brazing or silver soldering joints.

- 5.25 After pipework has been fixed in position, dry nitrogen must be passed through the system to remove oxygen prior to brazing or silver soldering joints.

- 5.27 The dry nitrogen must be at minimal gauge pressure during the brazing operation to eliminate the possibility of pin hole leaks.

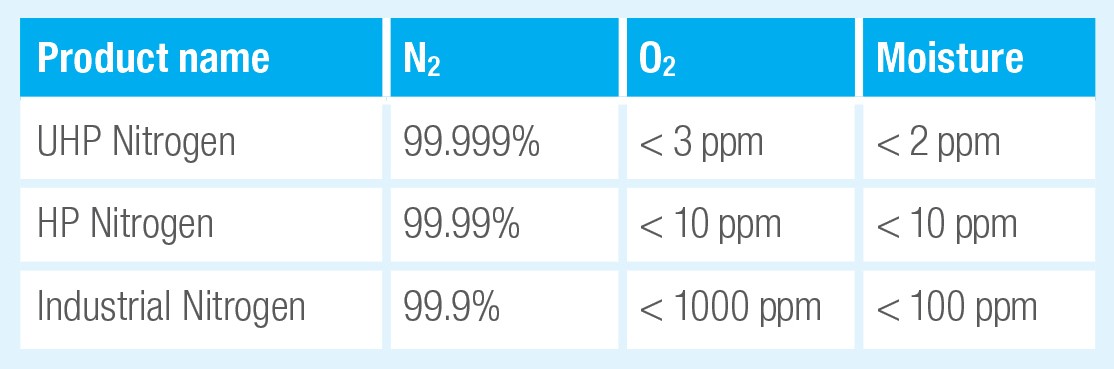

Historically, the type of dry nitrogen used during installation was branded as ‘Industrial Dry Nitrogen’. This labelling has (generally) now been replaced with ‘High Purity (HP)’ or ‘Ultra High purity (UHP)’ nitrogen.

The following graph highlights nitrogen grades. They are graded, at least in part, by moisture content. To use anything other than a dry, inert gas such as HP or UHP nitrogen, increases the risk of introducing unacceptable levels of moisture and oxygen (O2) into the HVAC-R system.

Back to newsletter

Contact Us

Contact Us About the ARC

About the ARC